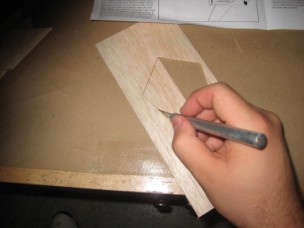

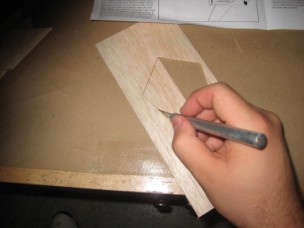

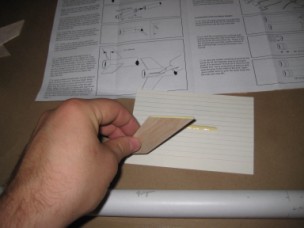

After you have the fins cut

out you then have to sand them to get them all completely uniform in

size, and to smoothen the surface a bit. I shape them using 120 grit

sandpaper, and smooth the faces of the fins with some 400 grit

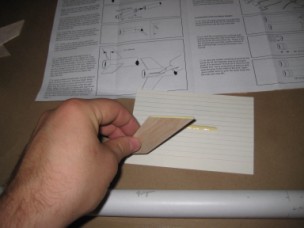

The next step in the

project was to connect the two tubes together. The

tubes are a good sturdy cardboard, and they supply a coupler to join

the two sections. First, one side of the coupler is lightly smeared

with some wood glue, then it is inserted into once section of tubing,

until inserted half way. I know what your thinking, "oh crap! he uses

that expensive stuff.... 'Premium Wood Glue'." Haha. Bad

joke

over. So now the glue is allowed to set for a few minutes.

So now that the glue has had a few minutes to set and adhere to the

coupler & body section, the remaining exposed half of the

coupler

is lightly smeared in wood glue, and the second section of body tubing

is set over that until flush with the other tube.

Now

that the tubes are

together and the fins are sanded down, the fins are ready for mounting

on the rocket body. To attain maximum accuracy the supplied fin

mounting jig is taped together, and slid over the body. I then

proceeded to mark the spots at which the fins would be mounted, as well

as where the launch lug will be attached. The fins will also be mounted

3/4" from the bottom (aft) of the rocket, so that is marked wit the use

of my digital caliper (I know, a bit overkill).

Then a small amount

of wood glue is applied to the part of the fin that will attach to the

body, and it is pressed onto the body lightly for a few minutes until

the glue has set somewhat. I made a quick jig out of some scrap wood to

hold the rocket vertical while attaching the fins, it made the process

much easier.

The next step I took

was to put in the motor retaining ring, which was simply smeared with

wood glue, and inserted several inches (exact measurement forgotten)

into the aft of the rocket body. Then from there I assembled the 24mm

motor adapter, which went together quite easily. Again, I went overkill

with accuracy, using my digital caliper to measure out things.

The next step is to secure the launch lug to the body, which was quite

an easy task.

Finally the streamer

is attached to the shock cord, and the shock cord is the attached to

the nose cone, as well as the body. To make sure the knot holding the

nose cone to the shock cord holds, I added a few dabs of superglue to

the knot. That way, I never have to worry about the knot coming loose,

and destroying a perfectly good rocket.

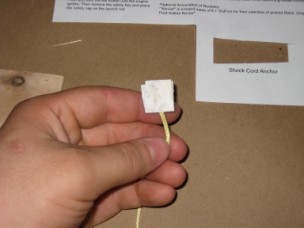

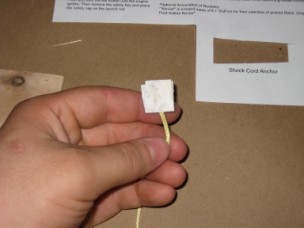

Then the other end of the Kevlar shock cord must be attached to the

body itself.

Apogee

supplies you with a nice cutout which is folded

upon the shock cord with liberal dousings of glue. It is then attached

several inches deep inside of the forward body tube.

Finally; we have a working model Rocket! Here are a few pictures of the

rocket finished before painting.

Update 11/15/09: I painted the rocket about a week back, and

decided to do a two-tone dark blue, on the aft, fading to a pumpkin

orange up top. Started with a nice layer pf primer, than just finished

off with the blue and orange. It was a nice and simple gloss spray

paint job, and I really cant complain. Looks good. (at least I think so)

Hope

you enjoyed. This was a nice fun weekend project that would be perfect

for any beginning rocketeers. Since the rocket can accept Estes type

motors it is very inexpensive to fly, and since it uses a streamer

recovery system, it comes down pretty close to the launchpad, so no

mile hikes are needed to recover the rocket. Also, the

Apogee

Aspire

can

handle large composite 29mm motors, so this is truly a two for one

deal when you buy this excellent kit. On one hand you get a great,

inexpensive model rocket, which is cheap to fly and quite fun, and on

the other hand you get a high performance 29mm motor consuming, mile

high capable supersonic beast. Absolutely the best of both worlds, for

only about $20. How can you beat that!?!?!