Making

Elemental Potassium (K)

I

recently began a new hobby; collecting elements. Of course

with

such a hobby comes a lot of chemistry. Especially due to the fact that

whatever elements I can isolate by myself, I will. I believe it is much

more fulfilling and educational to isolate an element yourself than

just

purchase it from some online retailer in a little vial or ampoule. Of

course with chemistry there is inherent danger. So this disclaimer is

necessary:

Disclaimer:

All experiments in this text should be done outside or in a fume hood

with proper lab and safety equipment. It must be done by or under the

direct supervision of someone experienced with chemistry laboratory

procedures. These procedures must never be done in the presence of

young children or animals.

First I want to thank the many contributors on

ScienceMadness, as

their procedures and successes are what helped me achieve success with

this reaction. Credit is also owed to the author of the thread at

http://www.versuchschemie.de/topic,14677,-Synthese+von+Kalium.html.

I performed this reaction 5 times without success. My

6th and 7th attempts were successful. What I determined caused failure

in reactions 1-5 was the use of impure (95%) magnesium.

Be sure to check out my latest and most successful attempt at isolating elemental Potasisum here: (Revisited) Making Elemental Potassium (K)

So

here is the outline I wrote myself for the procedure:

The

reactants were as follows:

- 2g

high purity Mg. approx 75 mesh, very low oxide. ( I actually made this

immediately before the reaction from a high purity ingot) You can

produce this with a medium metal file or as I did using a milling

machine to produce very fine turnings. My source for the magnesium was

an Amazon seller named GalliumSource who sells small 99.9% pure

magnesium ingots. I highly recommend using Magnesium of this purity, as

lower puritys I tested did not produce success. Magnesium

Metal Ingot, 99.95% Pure, 8 Ounces

- 0.8mL

t-Butyl alcohol. t-Amyl can also be used with even greater success. This acts as the catalyst in

the

reaction and is somewhat difficult to find but can sometimes pop up on eBay.

- 35mL

ultra pure paraffin

oil. Tetralin

is also reported to

work excellent but I was unable to obtain it. Due to Tetralins density

being

higher than potassium, the potassium coalesces into large balls on the

surface. Decalin can also be used with the same benefits of Tetralin.

Some other solvents reported to work are hypoallergenic baby

oil, medium kerosene lamp oil, mineral oil should work just fine, and

of course Shellsol D70, which is what was originally used as the

solvent for this reaction.

I

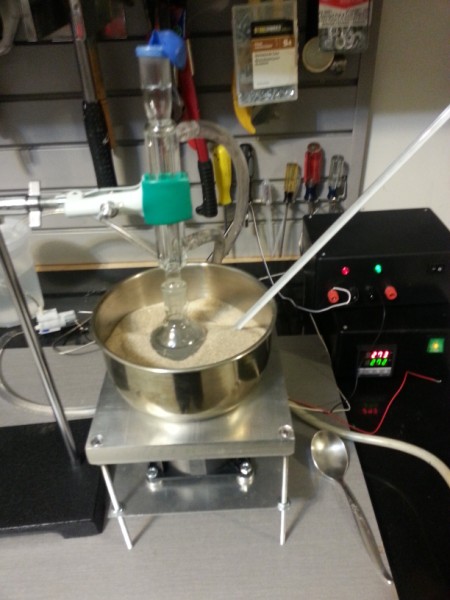

used a 50ml boiling flask, and a 200mm west condenser for reflux. I set

my hot

plate to 270*C and used a sand bath to heat the flask. A balloon with a

small

hole poked in it was fixed to the top of the condenser to minimize

atmosphere

from entering. Here is a picture of the setup:

First

the Mg was added to the flask, then

the KOH. The 35mL of

paraffin was then added, and heated in the sand bath to drive off all

water

within the KOH due to its hygroscopic nature.

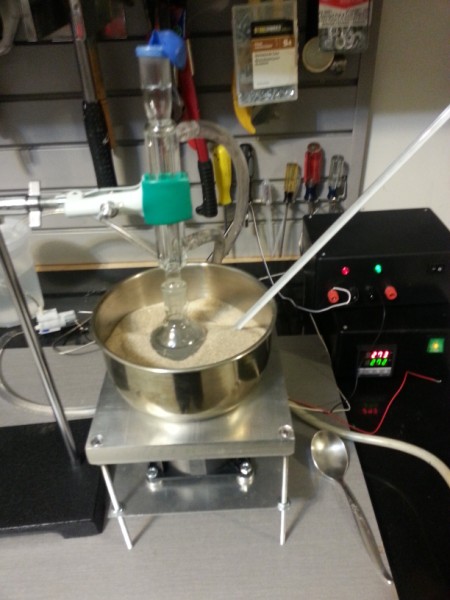

Note: The picture above shows the

reactants from one

of my first procedures (unsuccessful). The Magnesium

was only 95% pure which impeded the reaction, and the particle size of

the both Mg and KOH was too large.

The Mg helps speed the

displacement of water forming some MgO. Hydrogen evolution was noted in

small

quantities. After 30 minutes of heating, the t-butyl was added in small

.1mL

increments over the course of 2 hours. This was added by injecting

through the

balloon using a pipette to pierce the balloon and minimize atmospheric

contamination. After 3 hours small globules of potassium were noted as

seen below.

After 6

hours of reflux, the experiment was stopped, and allowed to cool. After

cooling

the reaction products were dumped into a large watch glass, and the

potassium

balls were extracted and stored under paraffin oil.

Final

yield was very poor due to my not allowing the reaction to progress

further upon

which the potassium would have coalesced much more, but my time was

limited.

But I can now add potassium to my element collection!

Some

Potentially

Helpful Notes:

Here is how I prepare the Magnesium turnings. If you have a

milling machine save your elbows some exhaustion! Please not that the

Magnesium turnings must be protected from the atmosphere as soon as

possible after being produced. I store it in sealed glass vials

immediately after making it. I first secure the Mg ingot into my

milling machines vise. After that I cut out a wide slit in the bottom

of a cardboard water bottle tray and slid it over the exposed part of

the Mg ingot. After setup I simply began milling a few thousandths off

at a time very slowly to produce extremely fine turnings.

Solvents: It seems that certian solvents make this reaction occur with

better yield and faster reaction times. Using paraffin, mineral oil, or

a kerosene based solvent, the yield is approximately 50% at best, and

with long reaction times (~4+ hours). When using solvents such as

Shellsol D70, the reaction time is still long (~4 hours), but the yield

is greatly improved with many experimenters reporting yields greater

than 80%. Finally when Tetralin or Decalin are used, the reaction time

seems to speed up greatly, and the yield is also high much like with

Shellsol. Some report reaction times of approximately one hour using

Tetralin.

Conclusion:

Although my production of elemental Potassium was successful, the final

yield was very poor since my potassium refused to coalesce. This may be

sue to my solvent or another unknown factor in my experiment. I will

try to use different solvents in future replications of this synthesis

in order to determine which solvents are most effective to promote

potassium coalescence.