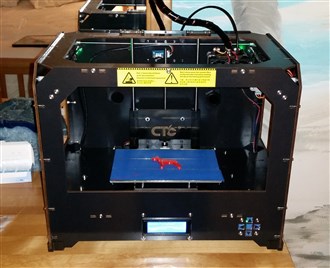

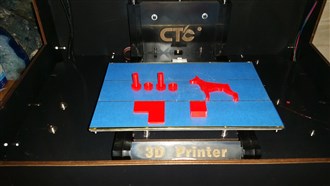

Above you can see a few of the things I have printed on the

CTC 3D printer. As you can see, the finish is not perfect, but with any

type of FDM printer you will get such a surface texture. Overall I have

been very happy with the printer, it can create extremely intricate

parts in a very reasonable amount of time with a good surface finish.

I also upgraded the firmware to Sailfish, and that has even further

improved the printer, allowing for changing the bed temperature,

extruder temperatures, and movement/extrusion rates on the fly, which

is extremely useful. To download Sailfish, check out the

Thingiverse page which has the download information and a great tutorial on how to upload the firmware.

All in all, I believe that for $500 this machine is every bit as good

as the equivalent Makerbot, which costs four times the price. It is

well worth every penny I spent on it and has been useful in creating

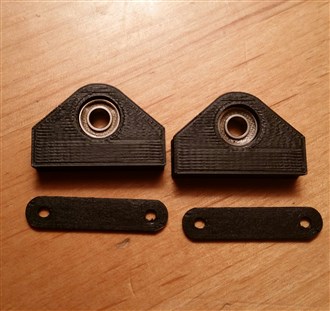

replacement parts for my tools in the garage. With very minor upgrades,

it can become a very capable machine. I also have a Thingiverse page,

where I designed a LED fixture mount for the printer, so that you can

light up the workspace and keep a better eye on your prints. Check it

out below and see my Thingiverse page

here.

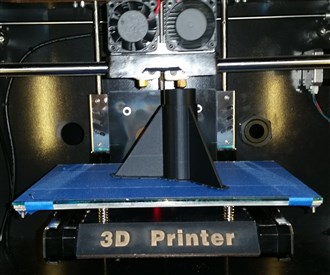

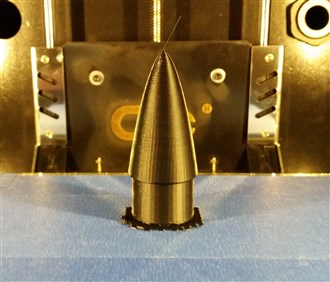

Recently,

I also built a model rocket using the CTC printer, using the stout

cardboard tube from the center of an Reynolds Wrap aluminum foil box as

the body, printing the nosecone and aft section of the rocket was a

breeze! Check it out: